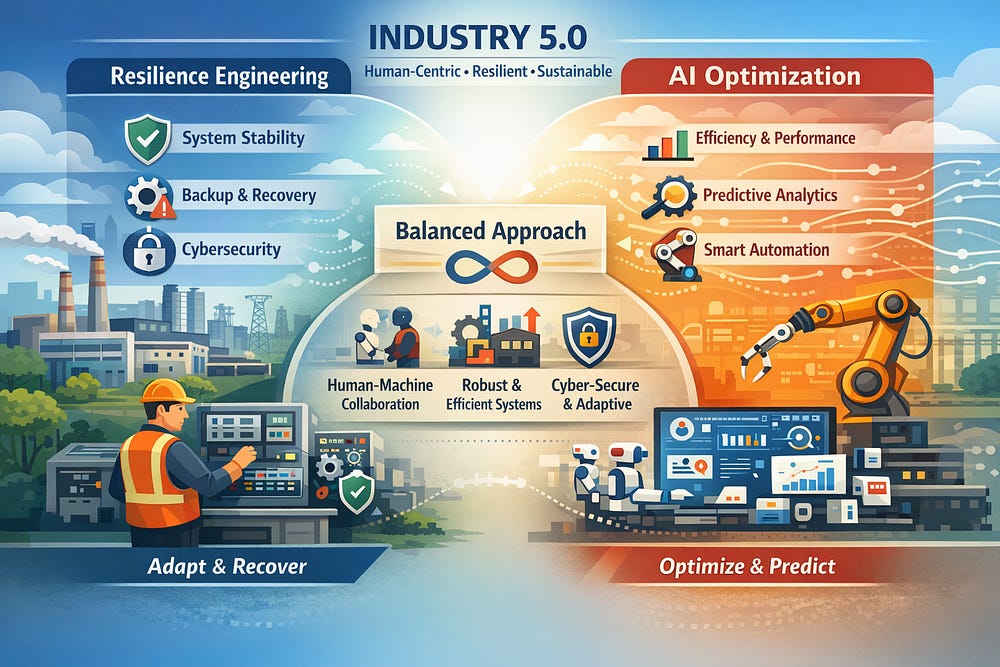

Resilience Engineering vs AI Optimization in Industry 5.0

By Muhammad Ali Khan ICS/ OT Cybersecurity Specialist — AAISM | CISSP | CISA | CISM | CEH | ISO27001 LI | CHFI | CGEIT | CDCP

Industry 5.0 is transforming the way industries operate. Unlike Industry 4.0, which focused mainly on automation and efficiency, Industry 5.0 emphasizes human-centric, resilient, and sustainable industrial systems. It aims to combine advanced technology with human skills to create systems that are not only efficient but also robust, adaptive, and safe.

In this context, two major approaches stand out: Resilience Engineering and AI Optimization. Both promise better performance, but they focus on very different goals. Understanding how they compare and complement each other is crucial for industries preparing for the future.

What is Resilience Engineering?

Resilience Engineering (RE) is the practice of designing systems that can adapt, recover, and continue to function under unexpected conditions. Unlike traditional risk management, which tries to prevent failures, RE accepts that failures can happen and focuses on how systems respond and recover.

In industrial settings, this means designing processes, equipment, and control systems that maintain safe operation even when errors, attacks, or disruptions occur. For example:

In a power plant, resilience engineering ensures that backup generators, control loops, and emergency protocols work even if primary systems fail.

In transportation, resilient traffic management systems can reroute vehicles automatically during sensor failures or cyber incidents.

From a cybersecurity perspective, resilience engineering encourages systems to tolerate attacks and misconfigurations, instead of relying solely on prevention. It ensures that critical operations continue even under compromise, which is essential in operational technology (OT) and industrial control systems (ICS).

Key principles of Resilience Engineering:

Anticipation: Identify potential disruptions before they happen.

Monitoring: Continuously observe system performance to detect early signs of trouble.

Response: Have protocols to respond quickly to unexpected events.

Learning: Adapt based on past failures to improve future resilience.

What is AI Optimization?

AI Optimization uses artificial intelligence, machine learning, and advanced analytics to improve operational performance. Unlike resilience engineering, AI focuses on predicting the best outcomes and making decisions to maximize efficiency, productivity, and cost-effectiveness.

Examples include:

Manufacturing: AI algorithms optimize production lines to reduce waste, predict machine failures, and improve scheduling.

Energy: Smart grids use AI to balance supply and demand in real-time, reducing energy loss.

Logistics: AI predicts traffic patterns, warehouse flows, and delivery routes to minimize delays.

AI optimization can also support cybersecurity by identifying anomalies, predicting threats, and recommending automated responses. However, AI systems themselves can be vulnerable to adversarial attacks or unexpected inputs, which is where resilience engineering becomes critical.

Key aspects of AI Optimization:

Data-driven decision making: AI learns from historical and real-time data.

Automation of routine tasks: Reduces human error and increases efficiency.

Predictive analytics: Anticipates failures or inefficiencies before they happen.

Continuous improvement: AI models refine themselves over time with more data.

Industry 5.0: The Context

Industry 5.0 builds on Industry 4.0 technologies but shifts focus to human-centric, resilient, and sustainable systems. Its goals include:

Collaboration between humans and machines: AI and robotics assist humans, rather than replace them.

Resilience: Systems must continue operating under failures, attacks, or unexpected conditions.

Sustainability: Reducing waste, energy consumption, and environmental impact.

This combination of efficiency, adaptability, and human focus makes Industry 5.0 a complex ecosystem. Here, both resilience engineering and AI optimization play critical roles, but they address different needs.

Strengths and Weaknesses

Resilience Engineering Strengths:

Maintains critical operations under attack or failure.

Supports human decision-making and situational awareness.

Reduces risk of catastrophic failures.

Weaknesses:

Can be costly to implement redundancies.

May not optimize efficiency; focuses on survival rather than speed.

AI Optimization Strengths:

Improves operational efficiency and cost-effectiveness.

Can identify patterns humans cannot see.

Supports predictive maintenance and proactive decision-making.

Weaknesses:

Vulnerable to data errors and adversarial attacks.

Over-reliance on AI can reduce human situational awareness.

May not perform well during unexpected disruptions outside training data.

Complementary or Conflict?

In Industry 5.0, resilience engineering and AI optimization are largely complementary, but balance is critical:

Complementary:

AI can optimize operations, while resilience engineering ensures the system survives failures.

AI-driven monitoring can support resilience by detecting anomalies early.

Potential Conflict:

AI systems may make decisions that maximize efficiency but reduce redundancy, weakening resilience.

Over-automation can reduce human intervention, which is essential for a resilient response during unexpected events.

Best practice: Integrate both approaches:

Use AI to optimize performance without compromising redundancy and safety.

Apply resilience engineering principles to ensure AI-driven systems remain robust under failures.

Maintain human oversight for critical decision points.

Industry Examples

Manufacturing:

AI optimizes assembly lines, predicts machine failures, and reduces downtime.

Resilience engineering ensures that if a robot fails, production continues manually or via backup processes.

Energy:

AI balances grid supply and demand efficiently.

Resilience engineering ensures that power distribution continues even if sensors fail or a cyberattack occurs.

Transportation:

AI predicts traffic and schedules shipments efficiently.

Resilience engineering allows rerouting, emergency braking, and safe operation during sensor or system failures.

Cybersecurity Implications

Both approaches affect cybersecurity differently:

Resilience Engineering: Focuses on tolerating attacks. Even if an attacker compromises part of the system, critical operations continue. It emphasizes redundancy, safe failover, and rapid recovery.

AI Optimization: Can detect anomalies and respond to attacks automatically. However, AI systems themselves are targets for cyberattacks, such as data poisoning, adversarial inputs, or model theft.

Recommendation: Combine both. Build resilient systems first, then overlay AI optimization to enhance efficiency and monitoring.

Future Trends

Hybrid Systems: Industry 5.0 will increasingly integrate AI optimization and resilience engineering into hybrid systems.

Human-AI Collaboration: Humans will supervise AI systems, using resilience principles to guide interventions during unexpected events.

Cyber-Physical Security: Resilience engineering will expand to cover AI-driven decisions, ensuring safety even in cyber-physical attacks.

Sustainable and Adaptive Systems: AI optimization will reduce waste and energy use, while resilience engineering ensures these systems are robust under change.

Recommendations for Industry 5.0 Adoption

Prioritize resilience first: Design processes and systems that can survive failures or attacks.

Integrate AI carefully: Use AI for optimization, but ensure it does not reduce system redundancy or human oversight.

Invest in human training: Humans remain critical for supervising AI and responding to unexpected situations.

Monitor continuously: Use AI analytics to detect anomalies, but validate with resilience-oriented protocols.

Plan for failures: Test backup systems, emergency protocols, and AI behavior under stress.

Conclusion

In Industry 5.0, both Resilience Engineering and AI Optimization are essential, but they serve different purposes. Resilience engineering ensures robustness and survivability, while AI optimization drives efficiency and predictive performance.

The real power lies in combining them thoughtfully. Organizations that integrate human-centric, resilient systems with AI optimization will not only survive disruptions but also thrive in a highly automated, interconnected, and unpredictable industrial world.

Industry 5.0 is not just about making systems smarter, it’s about making them smarter, safer, and more human-aware.

.png)

Comments

Post a Comment